Leveraging 23 years of high-precision gear manufacturing experience, Kean specializes in high-volume custom gear solutions. Backed by globally leading equipment, over 30 patented technologies, and a scalable production capacity exceeding 35,000 non-standard parts annually, we provide clients with high-precision, cost-effective custom gears that meet the most stringent transmission requirements.

Our core business involves customization based on customer-provided drawings and reverse engineering from physical samples. If you need custom gears or gear sets, Kean's engineers offer the necessary expertise to propose solutions that meet or exceed your exact specifications.

All our gear products come with a 3-year warranty, and we offer free replacement for any quality issues not caused by gear design. Our commitment to reliable quality is guaranteed by certifications including GB/T19001-2016, ISO9001:2015, AS9100D, and Classification Society approvals.

We provide flexible customization options to fit your unique needs:

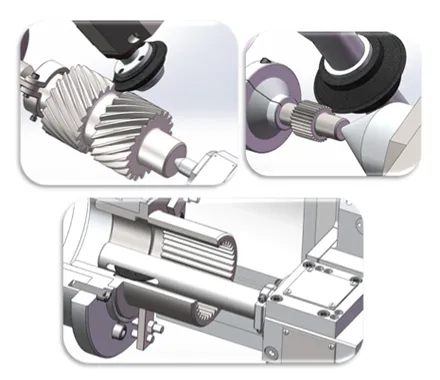

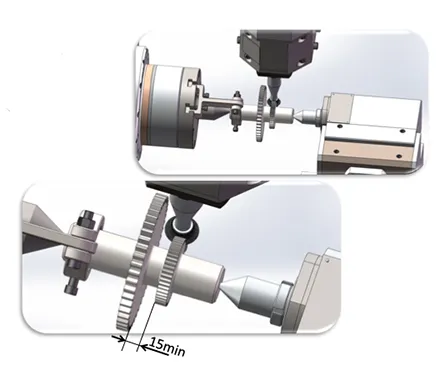

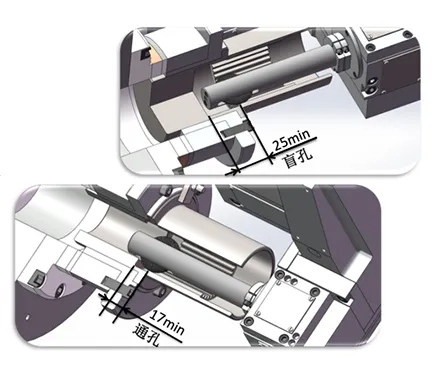

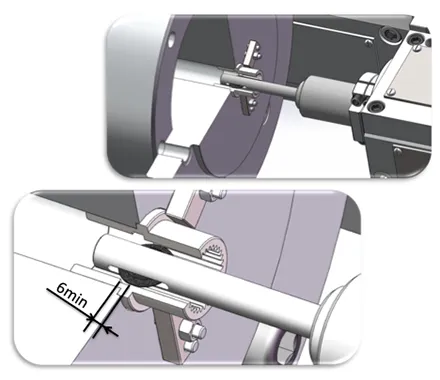

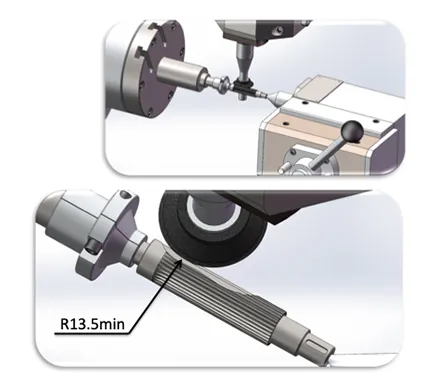

Our advanced capabilities enable a wide range of specialized grinding and machining processes:

Through one-on-one needs analysis and technical integration, we ensure that gear parameters (module, pressure angle, face width) and material selection highly match equipment operating conditions and load characteristics. This achieves transmission efficiency and service life that traditional standard gears cannot.

We customize gear structures based on specific scenarios, for example, using carburizing/nitriding treatments to enhance wear resistance, or designing non-standard tooth profiles to reduce noise. This is particularly beneficial for high-requirement fields like aerospace and precision instrumentation.

While the initial cost may be slightly higher than standard parts, the long-term comprehensive cost can be reduced by over 30% by extending maintenance cycles, minimizing downtime, and adapting to equipment upgrade needs. Bulk orders also enjoy tiered pricing discounts.

We achieve superior processing accuracy by utilizing equipment such as the Gleason Phoenix grinders (USA), KAPP gear grinders (Germany), and Gleason inspection systems.

We support orders starting from 1 piece, with emergency order delivery times shortened to 30 days. Standard ground gear orders are delivered within 45-60 days.

We provide end-to-end service, from initial requirements analysis to after-sales technical support, with a dedicated team of professional engineers ensuring continuous follow-up and offering a 36-month quality guarantee period. Our process includes: Client Drawing Reception - Parameter Confirmation & Communication - Custom Quantity Confirmation - Custom Time Confirmation - Quotation - Contract Signing - Advance Payment - Production Completion - Final Payment - Shipment - After-Sales Technical Support.

Contact us today to customize high-precision gear transmission parts for your specific needs!

ka@keancn.com